Titanium Foil

Siddhgri Tubes is your trusted partner for precision-engineered titanium foil manufacturing. With over a decade of industry excellence, we are dedicated to crafting titanium foil perfectly aligned with your unique project requirements. When you choose Hele, you’re opting for unparalleled quality, delivered promptly every time.

Other Availability Titanium Foil Grades – In stock

Custom Titanium Foil

Siddhgiri Tubes is a leading titanium foil manufacturer based in China, renowned for its unwavering commitment to producing premium quality titanium foils tailored to our client’s specifications.

With years of extensive experience in the titanium industry, our team boasts advanced manufacturing facilities and unparalleled expertise in catering to a myriad of commercial, industrial, and research applications. Trust in Siddhgiri Tubes for all your titanium foil needs, where quality and customer satisfaction are paramount.

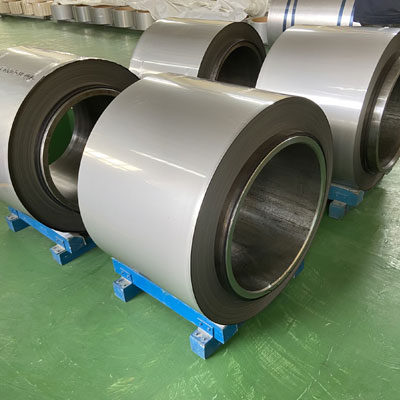

Titanium Foil

A lightweight yet robust sheet of pure titanium, renowned for its unparalleled strength-to-weight ratio. With its exceptional corrosion resistance and biocompatibility, this foil is the preferred choice for aerospace, automotive, and medical applications, bridging durability with safety.

Titanium Foil Sheet

Crafted from premium titanium, this foil sheet offers an optimal blend of durability and lightweight design. Ideal for aerospace, automotive, and medical sectors, it stands out for its superior corrosion resistance and biocompatibility, ensuring both strength and safety in its applications.

Titanium Alloy Foil

Merging the innate strength of titanium with other elements, this alloy foil delivers enhanced durability and versatility. Perfect for advanced industrial applications, it offers a harmonious balance between corrosion resistance and adaptability, making it a top choice for demanding environments.

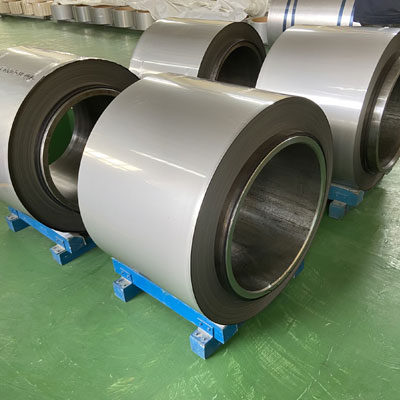

Titanium Coil

Custom Titanium Foil for your Specific Needs!

Siddhgiri Tubes, we are dedicated to precision engineering, turning your unique requirements into reality. Our custom-crafted titanium foils are designed to perfectly fit your specialized needs, ensuring unmatched quality and precision.

- Custom Thickness: Whether you need ultra-thin or robust gauges, we have you covered.

- Dimensions: We can adjust the width and length to precisely match your project’s specifications.

- Grades & Alloys: Choose from a versatile range to ensure optimal performance in any application.

- Surface Finishing: Select between a sleek mirror finish or a subtle matte appearance.

- Heat Treatment: We offer tailored heat treatment processes to achieve your desired mechanical properties.

Trust Siddhgiri Tubes for our commitment to excellence and unwavering dedication to crafting the ultimate custom titanium foil solution for you. Your vision combined with our

Beyond Just Supplying Titanium Foil

Siddhgiri Tubes isn’t just another titanium foil provider; we are your dedicated partner in tailor-made titanium endeavors, always striving to exceed your expectations.

Boasting over a decade in titanium foil craftsmanship, our seasoned team is unwavering in its dedication to premium quality, swift service, and competitive pricing. Our offerings span an array of titanium foil variants, encompassing diverse grades, dimensions, and densities, with the added advantage of bespoke adaptations to match your vision.

Titanium Grade Recommendation

Uncertain about the optimal titanium grade—Gr 1, Gr 2, Gr 3, Gr 5, Gr 7, Gr 9, Gr 12, or G23—for your venture? Entrust us to pinpoint the ideal grade that seamlessly aligns with your project’s prerequisites.

Technical Support

Should any query about our products arise, our doors are always open. Whether you seek insights from past projects or need on-site engineering expertise, our team is prepared to stand by your side.

Extensive range

Siddhgiri Tubes takes pride in presenting an expansive portfolio of titanium foils, strips, and similar derivatives, designed for a multitude of uses.

Fabrication Machining

With a rich legacy spanning a decade in the titanium sector, we stand equipped to ensure your titanium foil undergoes meticulous machining and finishing, matching your precise stipulations.

Why Choose Titanium Foil from Siddhgiri Tubes ?

At Siddhgiri Tubes, our unwavering commitment is to provide you with top-tier titanium foil solutions that truly set us apart. Our strong partnerships with industry leaders, metallurgists, and aerospace experts have endowed us with unparalleled knowledge, ensuring that the product you receive is tailor-made to your precise requirements.

- ISO-Certified Production Process: Proudly boasting an ISO9001 certification, Siddhgiri Tube’s manufacturing environment is pristine and rigor-free, guaranteeing an uncompromised standard of operations.

- Continuous Skill Enhancement: Our dedicated team undergoes rigorous training regimes, with a focus on refining their skill set and staying updated with industry advancements. This commitment ensures the utmost precision and quality in every order we fulfill.

- One-stop service: From shaping to precision cutting, our advanced machinery ensures top-tier results. Partner with us for tailored solutions and 100% satisfaction. Your ultimate titanium source.

- Supreme Quality Assurance: Our devotion to excellence is evident in the end-product. We procure only the finest raw materials, reinforcing our pledge to deliver unparalleled titanium foil solutions to our clients.

What is Titanium Foil?

Titanium foil is a slender sheet of titanium metal renowned for its exceptional strength-to-weight ratio and impressive resistance to corrosion. Its durability and compatibility with living tissues have earned it a prominent place in various industries, including aerospace, medicine, and electronics.

Features of Titanium Foil

Titanium foil stands out as a high-performance metal sheet renowned for its exceptional blend of strength, durability, and adaptability. Widely employed across diverse industries, from aerospace to medical applications, it offers a multitude of advantageous features:

- High Strength-to-Weight Ratio: Titanium foil possesses remarkable strength while being exceptionally lightweight. This property makes it an ideal choice for applications in aerospace and automotive industries.

- Corrosion Resistance: It exhibits outstanding resistance to corrosion, particularly in harsh environments such as seawater and chlorine-rich settings. This resilience is attributed to the formation of a protective oxide layer when exposed to oxygen.

- Biocompatibility: Titanium is biocompatible, meaning it is non-toxic to the human body. This characteristic makes it a top selection for medical implants and devices, ensuring patient safety and well-being.

- High-Temperature Endurance: Titanium foil can withstand elevated temperatures, making it invaluable in aerospace and industrial contexts where extreme heat is a factor.

- Flexibility: Despite its strength, titanium foil maintains a remarkable degree of flexibility. This quality enables it to be easily molded and shaped to cater to a wide range of industrial requirements.

Titanium Foil Classifications

Titanium foil, prized for its high strength and lightweight properties, comes in various forms tailored by thickness. Each type is optimized for specific applications across a range of industries. Here’s a detailed look:

| Titanium Type | Description | Applications |

| Ultra-Thin Titanium Foil | Thin sheets with a thickness of less than 0.1mm. | Precision instruments, micro components, and delicate assemblies. |

| Titanium Strip | Narrow bands between 0.1mm to 0.3mm thick and up to 500mm in width. Usually in rolled forms. | Electronic devices, connectors, and specialized mechanical components. |

| Titanium Coil | Broader strips with a thickness from 0.3mm to 4.75mm and a width over 500mm. | Automotive exhaust systems, aircraft structures, and heavy-duty equipment. |

Considerations Before Purchasing Titanium Foil

- Application Requirements: Begin by clearly defining the intended application of the titanium foil. Whether it’s destined for aerospace, medical, chemical, or other industries, understanding the specific use is paramount.

- Grade Selection: Choose the appropriate titanium grade that aligns with your application’s mechanical and chemical requirements. Different grades offer varying properties and suitability for distinct purposes.

- Thickness and Size: Determine the desired thickness and size of the foil. Consider the specific dimensions required for your project, as they play a vital role in its success.

- Corrosion Resistance: Assess the level of corrosion resistance needed for your application environment. The degree of exposure to corrosive elements will influence your choice of titanium foil.

- Surface Finish: Consider whether the foil requires a specific surface finish, such as polished or matte, to meet your project’s aesthetic or functional needs. The finish can impact both appearance and performance.

- Budget: Set a clear budget for your titanium foil purchase. Explore available options that align with your financial considerations while still meeting your quality requirements.

- Supplier Reputation: Conduct thorough research to choose a reputable supplier with a proven track record of delivering high-quality titanium foil. Customer reviews and testimonials can provide valuable insights.

- Certifications: Ensure that the titanium foil meets relevant industry standards and certifications. This step is crucial to guarantee the product’s quality and compliance with regulations.

- Customization: Check if the supplier offers customization options for the foil. Tailoring the product to match your specific project requirements can be advantageous in achieving optimal results.

- Lead Times: Confirm the supplier’s lead times for delivery. Timely delivery is essential to ensure that the foil arrives when needed, aligning with your project timeline.

Titanium Pipe Fittings Application Industries

- Textile machinery

- Oil and gas industry

- Pulp and paper industry

- Power plants

- Energy industries

- Furniture

- Pharmaceutical processing industry

- Modern architecture

- Home appliances

- Water waste projects

- Synthetic fiber

- Heat exchanger

- Fluid piping

- Dairy and food processing

People Also Searched for

titanium industrial pipe fittings, titanium pipe fittings exporter in india, astm b363 titanium pipe fittings in india, titanium pipe fittings manufacturers in india, titanium piggable bend, astm b363 fittings titanium 625, titanium buttweld fittings supplier in india, titanium buttweld fittings price, titanium alloy straight crosses, titanium 90° long radius elbows stockist, asme sb363 titanium pipe fittings, titanium collar, high titanium alloy pipe fittings supplier in india, titanium pipe nipple distributor, titanium pipe fittings price list, titanium alloy 180 deg long radius elbow, titanium lap joint stub end stockholder, titanium seamless elbow supplier, titanium long radius bend, titanium buttweld pipe fittings manufacturer in mumbai, titanium 90 deg short radius elbows dealers, astm b363 titanium long radius 45° elbows, astm b363 titanium 3d elbow, titanium alloy buttweld elbow price list india, titanium pipe fittings pressure rating, titanium pipe fitting manufacturer india, titanium butt weld long radius bend.